Pouducts

Your are here: Home >> Products >>Grinding Miller

The basic principles of grinding miller is when fluid and semi-fluid material go through the fixed gear and moved gear which is high-speed relatively linked, can be influenced by strong shear, friction and high-frequency vibration, and be effectively crushed, emulsified, homogenized. So that precision products can be made.

Directory

- Live Demonstration of Grinding Miller

- Structure of Grinding Miller

- Usage of Grinding Miller

- Characteristics of Grinding Miller

- Technical parameters of Grinding Miller

- Grinding Miller Finished Picture

Live Demonstration of Grinding Miller

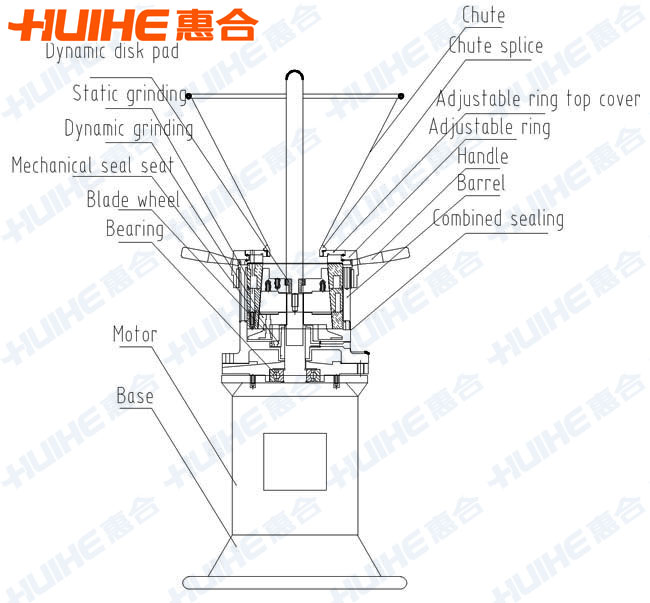

Structure of Grinding Miller

Usage of Grinding Miller

Grinding miller is mainly used in food, pharmaceutical, chemical and other industries to wet superfine grinding material, can be all kinds of semi liquid and emulsion material crushing, emulsion, homogeneous and mix.

Characteristics of Grinding Miller

Grinding miller equipment also called colloid mill, maintenance is convenient, suitable for high viscosity materials and large particles of the material.

Technical parameters of Grinding Miller

|

Model |

JML-50 |

JML-80 |

JML-100 |

JML-120 |

JMF-80 |

JMF-100 |

JMF-120 |

JMF-140 |

JMF-180 | ||

|

Emulsification fineness um 锛坰ingle cycle or multi-cycle锛 |

5~40 |

3~40 |

2~40 |

2~40 |

3~40 |

2~40 |

2~40 |

2~40 |

2~40 | ||

|

Adjustment range mm |

1-0.01 |

1-0.01 |

1-0.01 |

1-0.01 |

1-0.01 |

1-0.01 |

1-0.01 |

1-0.01 |

1-0.01 | ||

|

Output t/h change according to materials |

0.01-0.2 |

0.3-1 |

0.5-2 |

0.7-3 |

0.3-1 |

0.5-2 |

0.7-3 |

1-4 |

2-5 | ||

|

Motor |

Power kw |

1.1 |

3 |

5.5 |

7.5 |

4 |

5.5 |

7.5 |

11 |

15 | |

|

Pressurev |

380 |

380 |

380 |

380 |

380 |

380 |

380 |

380 |

380 | ||

|

Stirring speed r/min |

2880 |

2880 |

2880 |

2880 |

2880 |

2880 |

2880 |

2880 |

2880 | ||

|

Grinding diameter mm |

鈭50 |

鈭80 |

鈭100 |

鈭120 |

鈭80 |

鈭100 |

鈭120 |

鈭140 |

鈭180 | ||

|

Discharge port diameter 锛堟椂锛 |

鈭15 |

鈭25 |

鈭32 |

鈭40 |

鈭25 |

鈭32 |

鈭40 |

鈭40 |

鈭65 | ||

|

Cooling water pipe 锛堟椂锛 |

鈭1/8銆 |

鈭1/4銆 |

鈭1/4銆 |

鈭1/4銆 |

鈭1/4銆 |

鈭1/4銆 |

鈭1/4銆 |

鈭1/4銆 |

鈭1/4銆 | ||

|

Dimensions |

Length mm |

420 |

520 |

560 |

560 |

640 |

750 |

750 |

820 |

980 | |

|

Width mm |

280 |

400 |

420 |

420 |

550 |

620 |

620 |

700 |

800 | ||

|

Height mm |

760 |

900 |

950 |

950 |

1030 |

1080 |

1080 |

1250 |

1550 | ||

|

Weight kg |

45 |

84 |

113 |

135 |

210 |

275 |

295 |

325 |

450 | ||

Notes:

1. The technical parameters of colloied mill are standard configuration. Any specific requirements, please let us know.

2. JML-50 is experimental colloid mill, also can be changed to 220V voltage.

3. The process parameters that need provided when choosing the Colloid Mill: the nature of material, working pressure, temperature, specific requirements, etc.

Grinding Miller Finished Picture

- Differences between Vertical Colloi...

- Working principle of colloid mill

- Application difference between coll...

- Colloid mill

Add:33 Tangkang Road, Yuhang District, Hangzhou City, China

Tel : +86-571-86578098

Fax : +86-571-81604276

E-mail : manager@denverdesigndistrict.com

QQ:2355663251 phones/Wechat/Whatsapp:

+86 15268116877

Skype: huihemachine

QQ:2355663252

MSN:huihemachine@outlook.com