Pouducts

Your are here: Home >> Products >>Stainless Steel Fermentation Tank

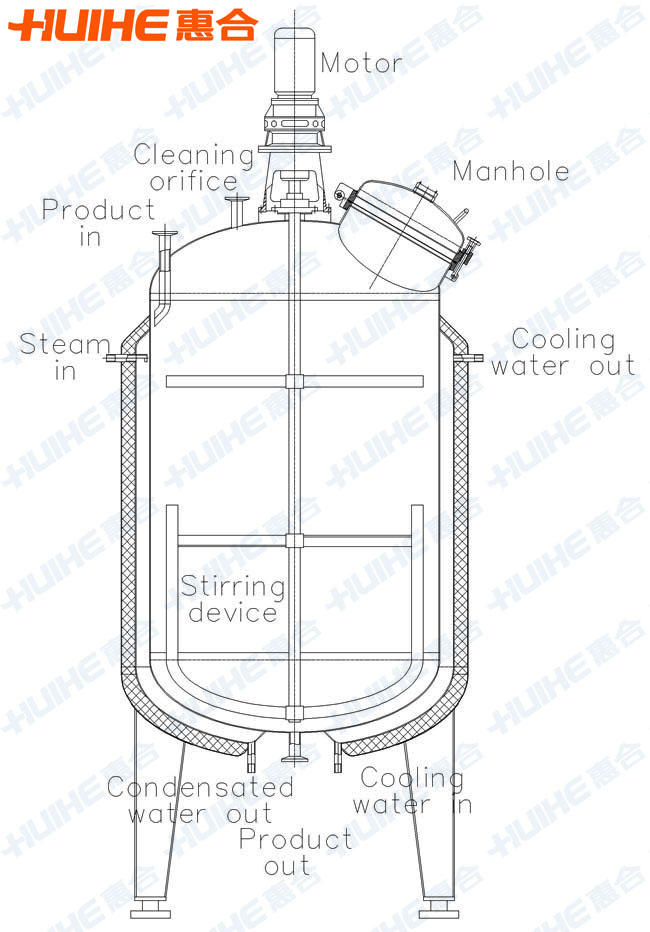

Stainless steel fermentation tank is widely used in the field of dairy, beverage, biotechnology, pharmaceutical and fine chemical industry. The tank equipped with laminate and insulating layer, can heat, cool and insulate. The tank body and up &down head (or prototype) are processed using R angle. The inner surface is mirror-polished, no dead corners, while the fully enclosed design ensures that the material is always at a state of no pollution to mix and ferment. The machine is equipped with air-breathing hole, CIP cleaning nozzle and manhole etc.

Stainless steel fermentation tank is widely used in the field of dairy, beverage, biotechnology, pharmaceutical and fine chemical industry. The tank equipped with laminate and insulating layer, can heat, cool and insulate. The tank body and up &down head (or prototype) are processed using R angle. The inner surface is mirror-polished, no dead corners, while the fully enclosed design ensures that the material is always at a state of no pollution to mix and ferment. The machine is equipped with air-breathing hole, CIP cleaning nozzle and manhole etc.

Directory

- Classification of Stainless Steel Fermentation Tank

- Structure of Stainless Steel Fermentation Tank

- Characteristics of Stainless Steel Fermentation Tank

- Technical Parameters of Stainless Steel Fermentation Tank

- Stainless Steel Fermentation Tank Finished Picture

Classification of Stainless Steel Fermentation Tank

1. According to Structure: opening on the head & conical sealed head on the bottom, up & down elliptical sealed head;

2. According to Heating Type: there are Steam Heating and Electric Heating;

3. According to Volume: there are 100L-1000L, also can design and facture in accordance with customers鈥 requirements.

Structure of Stainless Steel Fermentation Tank

Characteristics of Stainless Steel Fermentation Tank

1. It is a kind of stainless steel tank and can be CIP cleaned online, SIP sterilization (121掳C/0.1MPa).

2. Designed in accordance with sanitary requirement, so the structural design is very user-friendly and easy to operate. While the smooth transmission, low noise.

3. There is appropriate diameter; the stirring device is made on demand, energy-saving, stirring, good fermentation effect.

4. The inner surface is mirror-polished (roughness Ra鈮0.4µm); the weld of the inner pot with inlet, outlet, sight mirror and manhole use stretch flanging arc transition. No dead corners ensure the reliability and stability in the producing process.

2. Designed in accordance with sanitary requirement, so the structural design is very user-friendly and easy to operate. While the smooth transmission, low noise.

3. There is appropriate diameter; the stirring device is made on demand, energy-saving, stirring, good fermentation effect.

4. The inner surface is mirror-polished (roughness Ra鈮0.4µm); the weld of the inner pot with inlet, outlet, sight mirror and manhole use stretch flanging arc transition. No dead corners ensure the reliability and stability in the producing process.

Technical Parameters of Stainless Steel Fermentation Tank

|

Volume |

300L |

400L |

500L |

600L |

800L |

1000L |

1500L |

2000L |

3000L |

|

Body diameter锛坢m锛 |

桅800 |

桅800 |

桅900 |

桅1000 |

桅1000 |

桅1000 |

桅1200 |

桅1300 |

桅1600 |

|

Body height锛坢m锛 |

600 |

800 |

800 |

800 |

1000 |

1220 |

1220 |

1500 |

1500 |

|

Motor power锛坘w锛 |

0.55 |

0.55 |

0.75 |

0.75 |

0.75 |

0.75 |

1.5 |

2.2 |

3 |

|

Stirring speed(rpm) |

36r/min | ||||||||

|

Working pressure |

鈮0.09Mpa | ||||||||

|

Working temperature |

锛100鈩 | ||||||||

|

Accessories |

Sanitary manhole, cleaning ball銆乻afety valve銆乸ressure gauge | ||||||||

Notes:

1. The technical parameters of fermentation tank is standard configuration. Any specific requirements, please point out.

2. The jacket working pressure鈮 0.09Mpa also can be made according to customers鈥 requirements.

3. The process parameters that need provided when choosing the fermentation tank: the nature of material, working pressure, temperature, specific requirements, etc.

Stainless Steel Fermentation Tank Finished Picture

- Daily use of fermentation tanks' fi...

- Simply discuss how fermentation tan...

- Parsing the reaction vessel common ...

- Respectively in this paper, the use...

- The reaction kettle wall sticking r...

- Introduction of fermentation tank a...

- How do you determine the fermentati...

Add:33 Tangkang Road, Yuhang District, Hangzhou City, China

Tel : +86-571-86578098

Fax : +86-571-81604276

E-mail : manager@denverdesigndistrict.com

QQ:2355663251 phones/Wechat/Whatsapp:

+86 15268116877

Skype: huihemachine

QQ:2355663252

MSN:huihemachine@outlook.com