Pouducts

Your are here: Home >> Products >>High Speed Mixing Cylinder

High speed mixing cylinder is a kind of stainless steel tank .It is for low, medium and high viscosity of the liquid and solid dissolution, dispersion, crushing, grinding, mixing, homogenizing, emulsifying, with ultra-fine, high quality, high efficiency , the four low-cost advantages. Machine novelty, reasonable structure, fully mixed, easy to clean, easy to operate.

Directory

- Classification of High Speed Mixing Cylinder

- Usages of High Speed Mixing Cylinder

- Working principle of High Speed Mixing Cylinder

- Advantages of High Speed Mixing Cylinder

- Parameters of high speed mixing equipment

- High Speed Mixing Cylinder Finished Picture

Classification of High Speed Mixing Cylinder

1).Closed form and shaped vacuum

2).Capacity:100L,200L,300L,400L,500L and so on, it is also can be made according to customers鈥 requirement.

Usages of High Speed Mixing Cylinder

High speed mixing cylinder is widely used in the electronic materials, magnetic materials, ceramic glaze, new materials, bio-medicine, non-metallic minerals and other industries.

Working principle of High Speed Mixing Cylinder

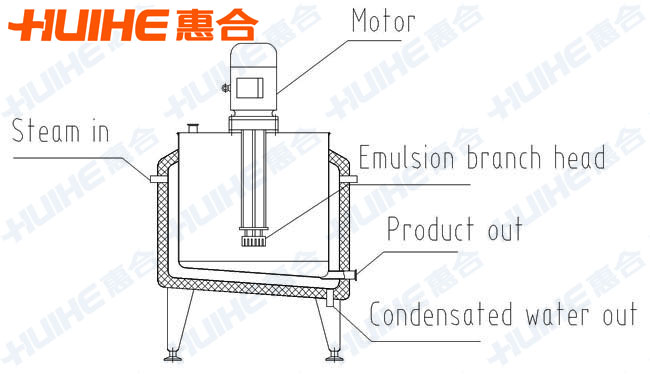

structure of high speed mixing cylinder

In the bottom of the horizontal cylinder, high-speed rotation of the rotor produces a large flow of high pressure centrifugal flow, centrifugal flow of material through the stator and rotor clearance precision when strong shear force, and accompanied by shock, extrusion, grinding and so on. Meanwhile, the bottom level of the high flow cylinder high-pressure centrifugal flow of materials in the cylinder body to produce three-dimensional vortex flow, after 10 minutes of this cycle, the material was quickly allow the solution, dispersion, crushing, grinding, mixing, homogenizing, emulsifying, the formation of fine slurry.

Advantages of High Speed Mixing Cylinder

1.High-speed mixing cylinder锛宼he more traditional mixed-cylinder liquid mixing efficiency equipment several times, especially in the traditional mixed fluid handling equipment, high-bonding groups of materials, hard granules, required a long time to fully mix problems, the use of JBG-cylinder high-speed mixing process, it becomes easy thing.

2.Mixing cylinder, turn the stator and pipe, valves, high-quality stainless steel, cylinder body, the outer surface polished.

3.Mechanical seal with a large compensation structure, wear-resistant, durable, easy to damage.

4.JBG / X high-speed mixing cylinder sealing surface to open and close, easy access to the washing machine space for perishable organic materials, easy to dry a mixture of solid materials.

Parameters of high speed mixing equipment

|

Volume |

100L |

200L |

300L |

400L |

500L |

600L |

800L |

1000L |

|

Cylinder diameter锛坢m锛 |

桅600 |

桅700 |

桅800 |

桅900 |

桅1000 |

桅1000 |

桅1000 | |

|

Cylinder height锛坢m锛 |

450 |

600 |

600 |

800 |

800 |

800 |

1000 |

1220 |

|

Motor power 锛坘w锛 |

2.2 |

2.2 |

3 |

3 |

4 |

4 |

5.5 |

7.5 |

|

Stirring speed (rpm) |

1750r/min | |||||||

Notes:

1. 1. The technical parameters of emulsification can is standard configuration, any special requires, please put forward.

2. The process parameters that need provided: the material properties, volume, special requirements, etc.

High Speed Mixing Cylinder Finished Picture

- Daily use of fermentation tanks' fi...

- Simply discuss how fermentation tan...

- Parsing the reaction vessel common ...

- Respectively in this paper, the use...

- The reaction kettle wall sticking r...

- Introduction of fermentation tank a...

- How do you determine the fermentati...

Add:33 Tangkang Road, Yuhang District, Hangzhou City, China

Tel : +86-571-86578098

Fax : +86-571-81604276

E-mail : manager@denverdesigndistrict.com

QQ:2355663251 phones/Wechat/Whatsapp:

+86 15268116877

Skype: huihemachine

QQ:2355663252

MSN:huihemachine@outlook.com