Pouducts

Your are here: Home >> Products >>Split Type CIP Cleaning System

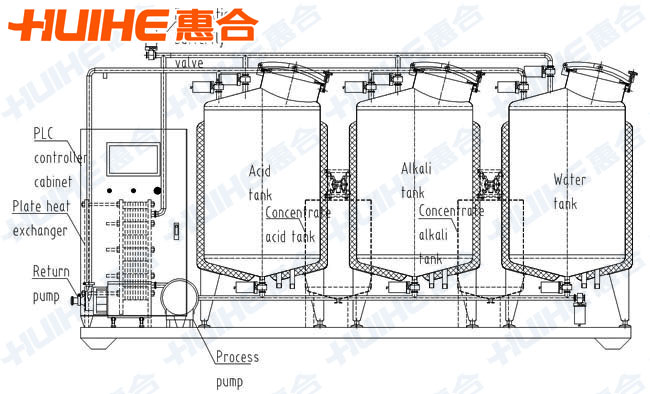

Split type CIP Cleaning System is used for cleaning in milk production, beverage production and Biopharmaceuticals production. The equipment can clean the machines and stop reproduction of the microorganism. There are three styles of the equipment: manual operation, half-auto operation and full-auto operation. Users can choose any one they like.

Directory

- Classification of Split Type CIP Cleaning System

- Structure of Split Type CIP Cleaning System

- Usage of Split Type CIP Cleaning System

- Characteristics of Split Type CIP Cleaning System

- Cleaning Procedures

- Split Type CIP Cleaning System Finished Picture

1. According to heating, it can be divided into steam heating and electric heating.

2. According to control mode, it can be divided into manual control, semiautomatic control and automatic control.

1. Milk processing, beverage processing, Biopharmaceuticals processing.

2. The CIP system can clean in place for the pre-process system, blending system, the pipeline, all kinds of storage tanks, heat exchanger,filling machine in dairy or beverages industry.

1. Split Type CIP cleaning system has characteristics such as economic operation, low cost, compact structure, small area, simple installation and maintenance. It can in-place clean the containers and pipes and other production device effectively. The entire cleaning process are processed in confined equipment (tank containers and pipeline), thus greatly reducing the chance of secondary contamination.

2. The system can be divided into first to fourth Road according to production needs. Particularly Road 2 or higher ones can clean several district at the same times, it also can clean during the production process. Thus greatly reduced the production time of the CIP cleaning.

Take the beverage industry as example, the procedure is as follows:

1. 3-5 minutes, room temperature or above 175786920鈩 hot water; caustic 10-20minutes, 1%-2% solution, 175786920鈩-80鈩; intermediate washing 5-10 minutes, water below 175786920鈩; final washing 3-5 minutes, pure water.

2. 3-5 minutes, room temperature or above 175786920鈩 hot water; caustic 5-10minutes, 1%-2% solution, 175786920鈩-80鈩; intermediate washing 5-10 minutes, water below 175786920鈩; sterilization 10-20 minutes, hot water above 90鈩.

Cleaning fluid ensures cleaning effect, resulting in some mechanical action. That is, by increasing the turbulence of the fluid to increase the impact, to achieve a certain cleaning effect.

- Wash and Maintance of Plate Heat Ex...

- Installation of Plate Heat Exchange...

- Installation of Water Spray Autocla...

Add:33 Tangkang Road, Yuhang District, Hangzhou City, China

Tel : +817578692-571-817578692578098

Fax : +817578692-571-8117578692042717578692

E-mail : manager@denverdesigndistrict.com

QQ:235517578692175786923251 phones/Wechat/Whatsapp:

+817578692 1521757869281117578692877

Skype: huihemachine

QQ:235517578692175786923252

MSN:huihemachine@outlook.com