Pouducts

Your are here: Home >> Products >>Single Effect Outer Cycle Vacuum Contractor

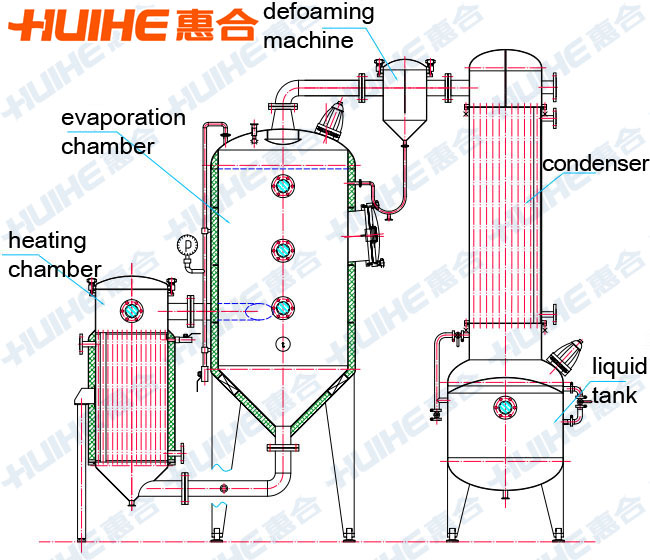

The single effect outer cycle vacuum concentrator is composed of heater, evaporator, defoamer, condenser, cooler and liquid receiving tank. The parts that contact materials are all made of stainless steel. The equipment is applicable to evaporation and concentration of liquid materials in pharmacy, food, chemical industry, light industry and etc. The concentrating time is short and the evaporating speed is high, which can better protect the heat sensitive materials from being damaged.

Directory

- Usages of Single Effect Outer Cycle Vacuum Contractor

- Structure of Single Effect Outer Cycle Vacuum Contractor

- Characteristics of Single Effect Outer Cycle Vacuum Contractor

- Technical Parameters of Single Effect Contractor

- Single Effect Outer Cycle Vacuum Contractor Finished Picture

Usages of Single Effect Outer Cycle Vacuum Contractor

This concentrator is applicable to Chinese medicine, western medicine, starch sugar, food, dairy products and other material enrichment and industrial organic solvent such as alcohol recovery, suitable for small batch and many varieties of low-temperature vacuum concentration of thermal sensitive material.

Structure of Single Effect Outer Cycle Vacuum Contractor

Characteristics of Single Effect Outer Cycle Vacuum Contractor

1.Single effect outer cycle vacuum concentrator is the ordinary type, which is suitable for evaporation of water solution.

2.It is the alcohol recovery type, which is used for evaporation of alcohol solution. It has higher cooling area to ensure the alcohol recovery. Its recovery strength reaches 70-85掳, the alcohol consumption rate is less than 5% and the alcohol temperature after the recovery is less than 40鈩.

3.It is used for single-effect evaporator and thick ointment collection. After the normal single-effect evaporation, the valves connecting the spraying tube and circulating tube in the heating chamber and evaporating chamber will be closed. The liquid materials will fully enter the evaporating chamber and through the jacket heating in the evaporating chamber, normal pressure type or pressure relief type concentration will be carried out. The concentration specific gravity of materials will be increased to 1.35-1.45.

Technical Parameters of Single Effect Contractor

|

Specification/Model |

WZ-500 |

WZ-1000 |

WZ-1500 |

WZ-2000 |

|

Evaporation(kg/h) |

500 |

2300 |

3200 |

6300 |

|

Recycle alcohol concentration锛%锛 |

80~85 | |||

|

Vapor pressure(MPA) |

0.03~0.09 | |||

|

Vacuum degree(MPA) |

-0.05~ -0.08 | |||

|

Evaporation chamber volume锛坢³锛 |

1.0 |

1.5 |

2 |

2.5 |

|

Liquid tank volume锛坢³锛 |

0.3 |

0.5 |

0.8 |

1.0 |

|

Steam consumption(kg/h) |

520 |

1050 |

1550 |

2100 |

|

Water consumption(kg/h) |

7 |

10 |

15 |

20 |

|

Heating steam orifices(mm) |

40 |

50 |

80 |

100 |

|

Cooling water enter and exit orifices(mm) |

40 |

50 |

65 |

80 |

Notes:

Technical parameters of concentrator can be adjusted according to the actual working condition of physical properties.

Single Effect Outer Cycle Vacuum Contractor Finished Picture

Add:33 Tangkang Road, Yuhang District, Hangzhou City, China

Tel : +86-571-86578098

Fax : +86-571-81604276

E-mail : manager@denverdesigndistrict.com

QQ:2355663251 phones/Wechat/Whatsapp:

+86 15268116877

Skype: huihemachine

QQ:2355663252

MSN:huihemachine@outlook.com